Follow-up posts

I finally laid out a PCB: Bike headlight circuit. Again

In the last post I complained about the poor regulation of a flashlight I bought. Apparently I was willing to dump unreasonable amounts of time to right this wrong, so I bought some parts, hacked them in and I now have a regulated flashlight driven by a big Li-ion rechargable cell.

The battery is a single 3500 mAh MNKE IMR 26650 cell. Apparently these are popular in the vaping community. Ok then.

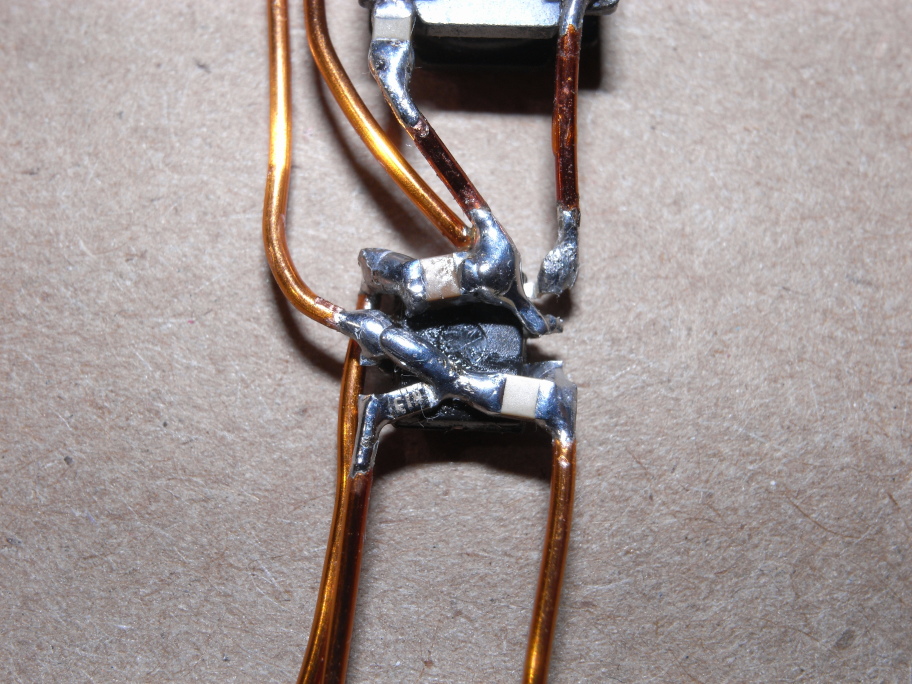

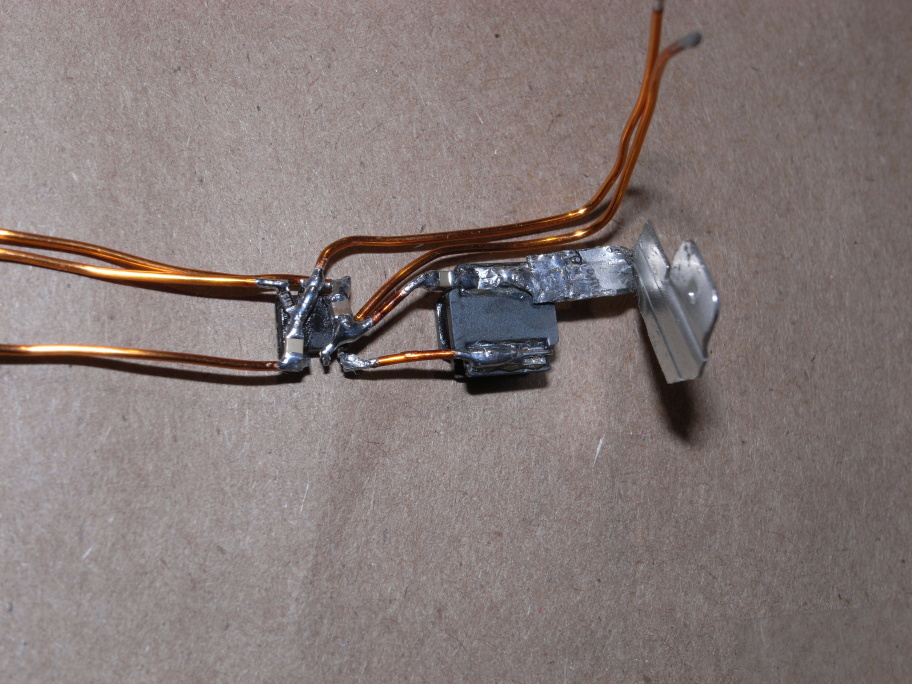

Very little is required to add regulation. I'm using an LED2000 driver IC to do all the work. This is a buck switching regulator that feeds back on current in order to drive an LED with a particular current. The circuit I built is the reference design for this IC. I added a TVS diode to absorb the voltage spikes that could result if the LED is disconnected as it is being driven; this is a potentially poor mechanical connection, so this is important. I added a PTC resistor to protect against short circuits. Furthermore, I'm using a switch controller IC and a MOSFET to interact with the on/off button. The circuit is not at all interesting.

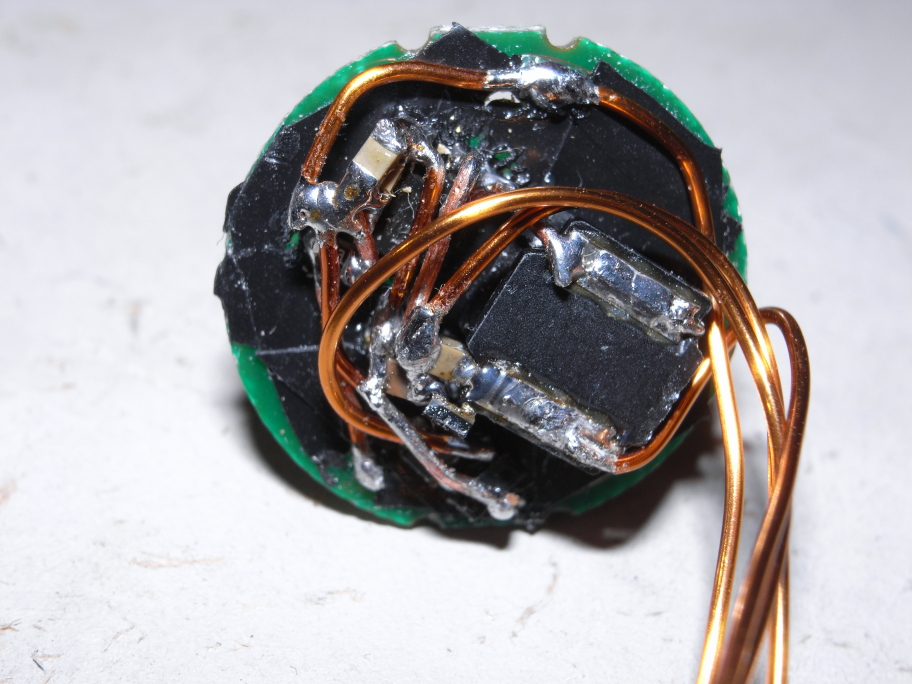

What is interesting is the construction. I never built a board, so this is all free-formed and then encased in hot glue at the end. I'm using 22-gauge magnet wire for everything. This is nicely thick and low impedance, but stripping it is a pain in the butt. In fact, this whole free-forming exercise was really time-consuming, and I don't feel particularly good about the results. The thing works right now, but I can easily imagine that it'll stop working at any point. At that point, I could make a PCB to construct something more reliable, but I've already put way too much time into this, so simply buying another light would be the answer.

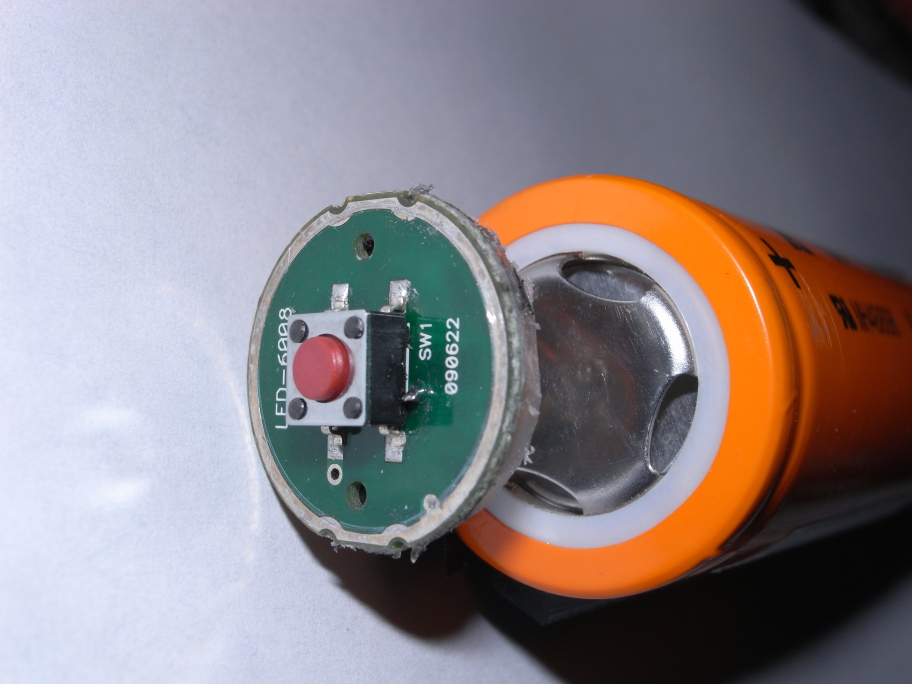

Before I realized that the button assembly in the cap could be opened, all the circuitry was meant to go in the gap between the battery and the housing:

After I figured out that I could get to the on/off button circuitry, I put everything into the cap:

Then encase in hot glue, and done: